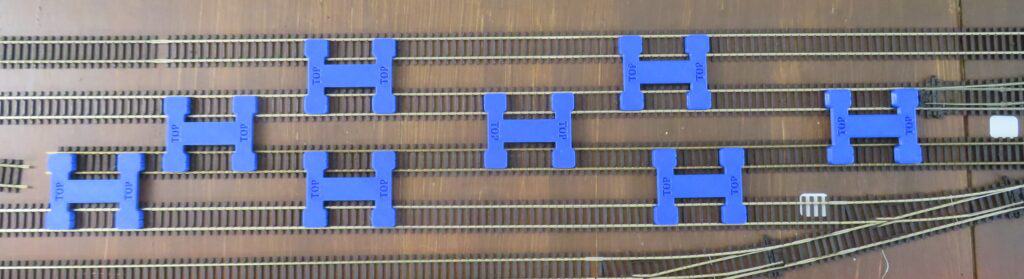

After a discussion with Roger last week, we fired up the 3D printer and produced a number of tools to help ensure that the tracks in the goods yard would be absolutely straight and parallel.

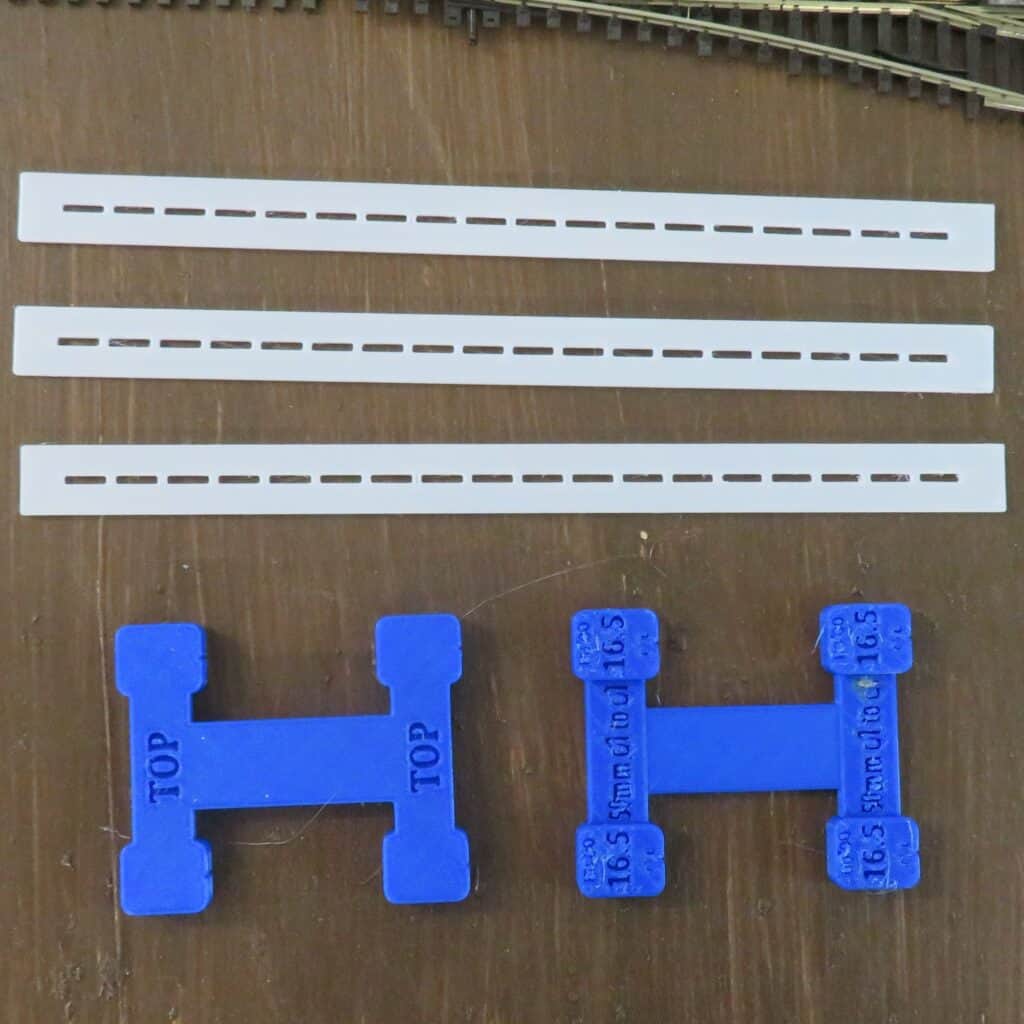

The H-shaped tools worked best and two versions were used to set the two track widths required (the white wider tools are not shown).

There was much interest from fellow members who could see how much easier the track laying process had become.

We often use 3D printers to produce complex shaped that would be difficult to produce using traditional tools.

However, these tools demonstrate how a 3D printer can produce many copies of the same design to aid the modelling process.